BENDSCAPE

Vienna 2023

Angewandte Festival Pavilion

Project Pitch

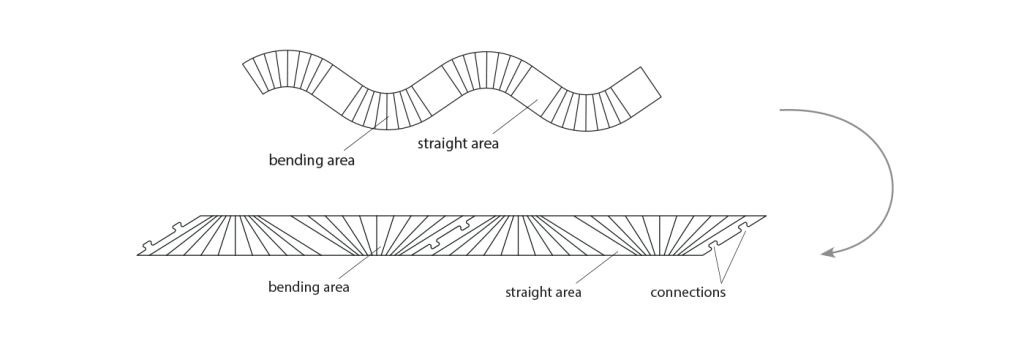

The project explores the design-to-production method of KERF bending with 3-axis machining and robotic milling. KERF bending is the process of bending wood by removing material.

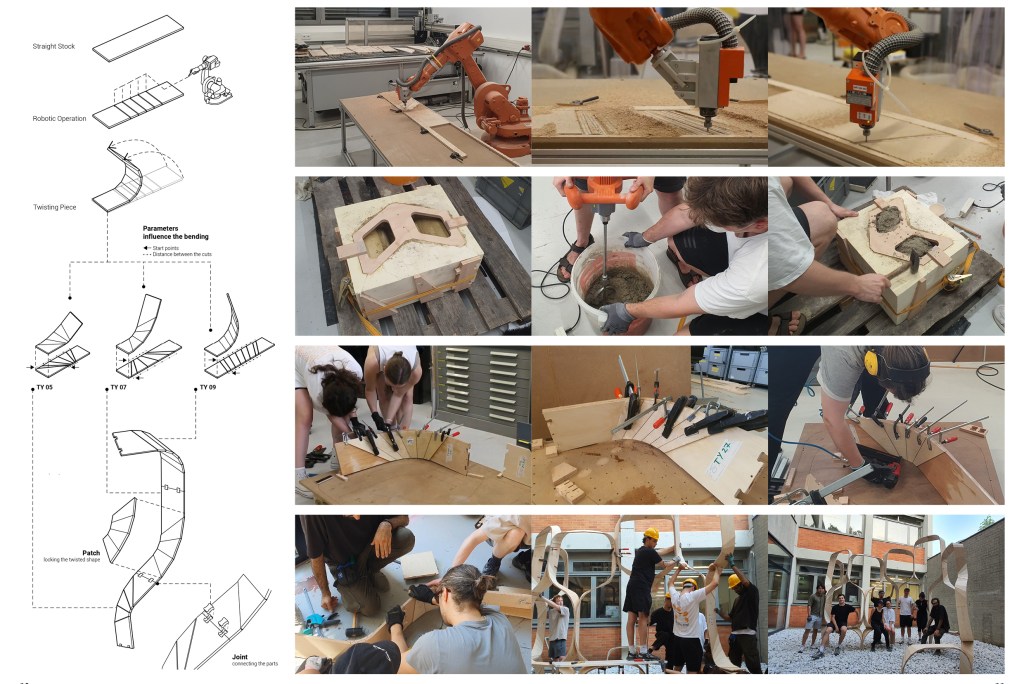

To understand how to design with materials, initial physical prototypes are used to explore different KERF cuts and the materials’ behavior, and developed with digital workflow into a full scale pavilion.

Material Efficiency – Transformation from round cutout into a straight piece

Shape Simulation – Comparison between shape out of curved and straight pieces

Physical Accuracy – Comparison between digital and physical performance

Design Development

From prototype to pavilion

01-Prototype

Out of several prototypes, the twisting loop is chosen to be developed into a pavilion. The twisting aesthetics and the high variability are the main reasons why it is chosen.

02-Twisting Strip

The initial sketch of the pavilion invites visitors to walk through thresholds as well as sit on benches, to experience different scales of the KERF element in relation to the body.

03-Playscape

Multiple configurations are tested for a more communal and exploratory playscape. Here, the bending elements are not yet modeled according to the logic of the KERF, but done with a quick and rough radial surface fillet.

04-Final Form

The approximation of the KERF bending to the concept sketch leads to a slight change in the scale and the geometry of the pavilion, due to fabrication limitations. The result is derived with the help of custom tools developed in grasshopper.

Digital Tool Development

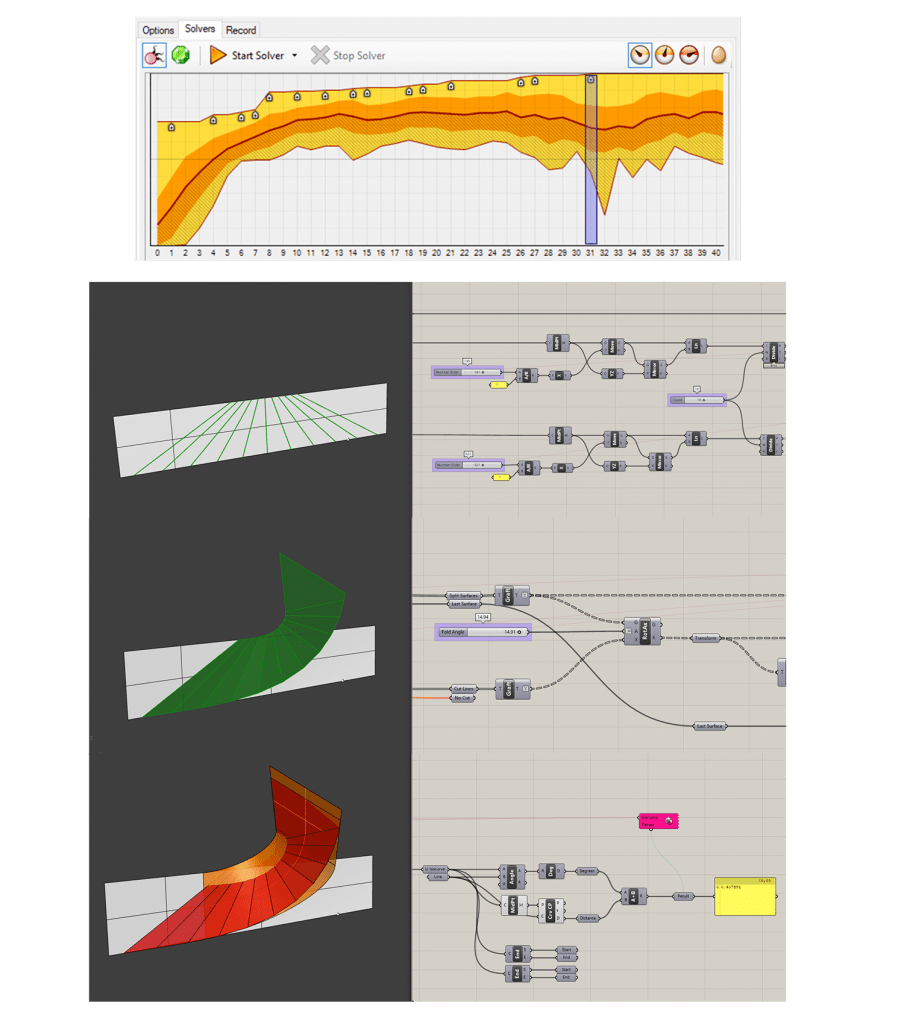

1-Angle Optimization – Optimize variables to match with the initial conceptual form

The final shape of the bent piece is based on a few variables: the number of KERF cuts, their arrangement and orientation on the piece, and the axial rotation at each cut section. A Grasshopper cluster with an evolutionary component is thus developed to optimize the variables and reach a form as close as possible to the initial conceptual form.

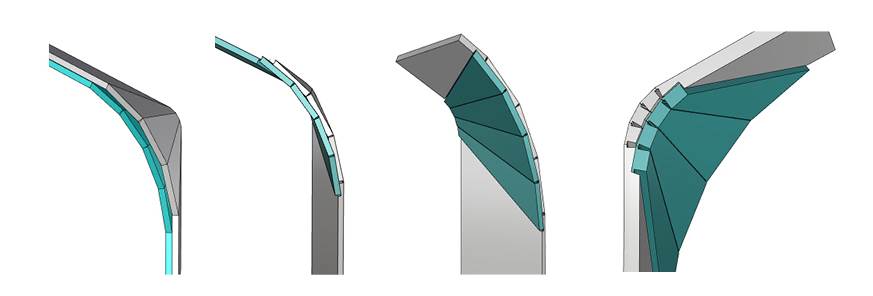

2-Reinforcement Solution – Develop and test patch solutions to structurally weak areas

Another problem is the structural stability and endurance at the KERF cut sections under loads. Different types of wood glue, including polyurethane glue are experimented. Also, different reinforcement patches were tested to find a final reliable solution. This added a new machining problem to the whole project, which is solved by involving the robotic arm into the production process.

3-Custom C# Component – Simulate the exact KERF shape and output fabrication data

Using the existing components of Grasshopper on a bigger scale is not reasonable due to the highly demanding memory and CPU requirement. Subsequently, a C# program is developed to quicken the design sketching. This plugin allows the user to easily play with the parameters and evaluate the results on the screen, and delivers the final bent geometry together with fabrication information, such as robotic machining toolpath and the patch geometry.

Credits and Data

BENDSCAPE is the result of a two-semester work by the students in Machining PRAXIS in Architecture I & II (2022-23), at the University of Applied Arts in Vienna’s Institute of Architecture.

Instructor:

Afshin Koupaei

Team Member:

Jasmy Chieh-Hsuan Chen

Louis Braunger

Naomi Neururer

Christina Braml

Leon Mackowski

Tilman Fabini

Orsi Kacso

Weichen Zhou

Petr Malasek

Zubin Tan

Jiayi He

Tomaz Roblek

Image courtesy of Afshin Koupaei, Leon Mackowski, David Kipp and Orsi Kacso.

BENDSCAPE is presented at CAADRIA 2024 held in Singapore, 29th International Conference of the Association for Computer-Aided Architectural Design Research in Asia.

BENDSCAPE is exhibited as part of the Angewandte Festival 2023.